Understanding Hydrostatic Test Pumps & Testing Requirements

Hydrostatic tests provide important safety assurances for pressurized vessels where catastrophic failure could result in serious injury or death. Ensuring vessels and their components have the structural integrity to safely withstand their maximum working pressure, hydrostatic testing helps to detect leaks or other defects in either build or materials that pose significant risk during vessel service life.

Commonly conducted across various industries, hydrostatic testing is critically important to the following:

- Oil & Gas: Pipelines, storage tanks and other transportation vessels

- Aerospace: Aircraft fuel tanks, pressure vessels and high pressure components

- Chemical: Tanks, reactors and chemical processing equipment

- Transportation: Gas cylinders and hazardous material containers

The frequency by which hydrostatic tests are conducted is determined by applicable regulations. As a general standard, hydrostatic testing is mandated every 5 to 10 years, although this range may fall short of what is required for vessels subject to intensive work cycles that regularly maximize working pressure.

Components Required for Hydrostatic Testing

The key components necessary to conduct a hydrostatic test are:

- A pressure vessel or component to be tested: This is the item that will be subjected to the hydrostatic pressure.

- A liquid: The liquid used for the hydrostatic test is typically water, but other liquids may be used depending on the specific requirements of the test.

- A hydrostatic test pump: This is the equipment used to apply the hydrostatic pressure to the pressure vessel or component.

- A pressure gauge: This is used to measure the pressure of the liquid in the pressure vessel or component during the test.

- A pressure relief valve: This is used to prevent the pressure in the pressure vessel or component from exceeding the safe working pressure.

- A means of monitoring for leaks: This may include visual inspection, dye penetrant testing, or ultrasonic testing.

Ensuring proper safety and equipment calibration procedures are followed prior to performing hydrostatic testing is critical to accident prevention and result accuracy.

Conducting a Hydrostatic Test

After proper safety and preparation standards have been accounted for, equipment can be connected to the vessel and test procedures can commence.

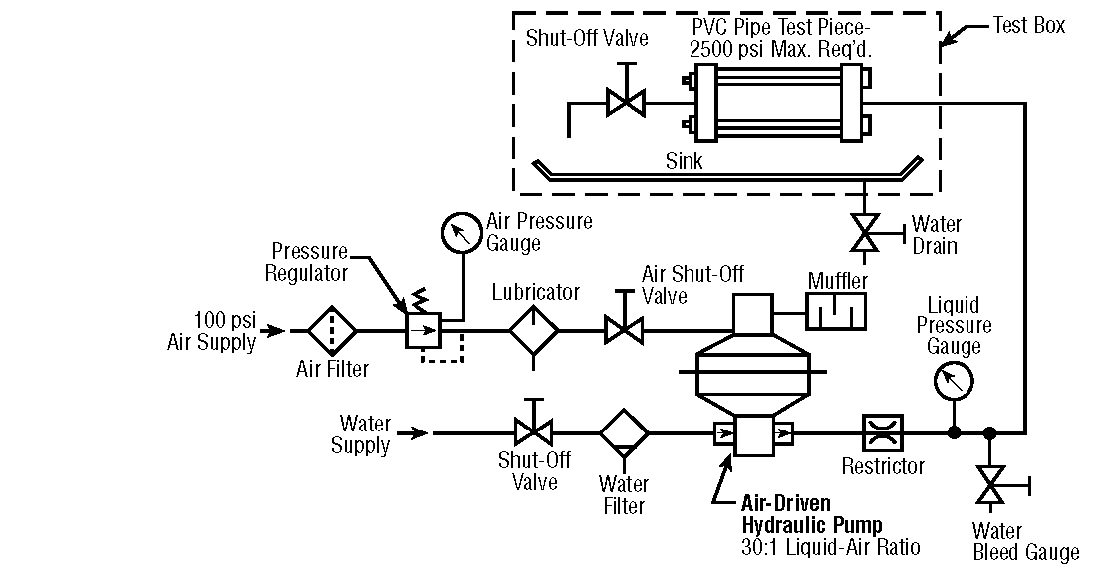

An example of a typical hydrostatic test procedure is as follows:

Running the test is straightforward, once the pump is connected to the system and is operating, water (or another test liquid) in the vessel is pressurized beyond typical operating pressure, typically 150% of designed working pressure, and monitored.

During the duration of the testing period, which is dependent on application, pressure is measured closely for drops that would indicate faults in the vessel. In some cases, this may be more obviously observed by liquids leaking from the vessel. The use of dyes in the test liquid is a common practice to distinguish test liquids, particularly if the hydrostatic test is performed on a coded vessel that is outdoors rather than being newly manufactured.

Once the determined test period has elapsed and no leaks are found, the test is complete. The system is slowly depressurized, liquid is drained and previous component removed for the sake of testing are reconnected.

Results are validated by the present pressure equipment inspector and the vessel is stamped to indicate a “pass” result. The stamped information will include the date of the successful test, identification of the test facility, as well as identifiers detailing design standards, manufacturer name and date, as well as the serial number for the vessel.

Selecting the Right Hydrostatic Test Pump

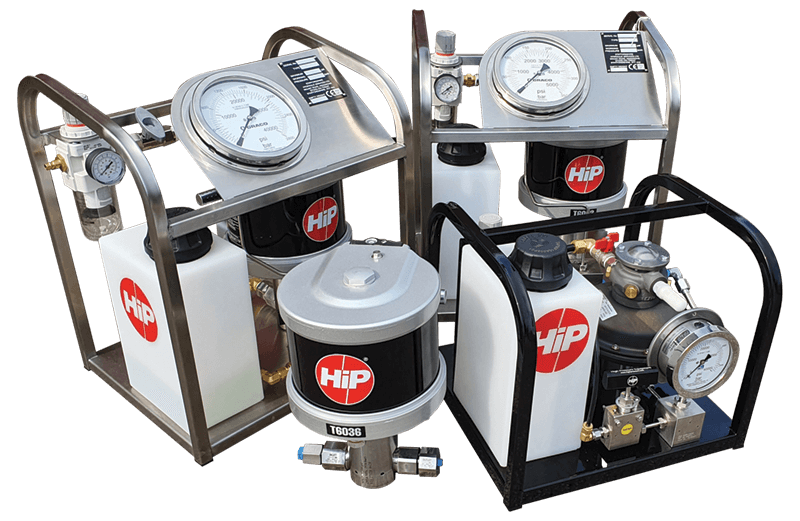

With sustained pressurization key to performing a successful hydrostatic test, selecting the right pump for testing applications is paramount to meeting the parameters necessary to merit a factual end result. Repeatability in performance at elevated pressure and simplicity in design are two factors that separate Graco High Pressure Equipment (HiP) air-operated pumps and packages.

With the ability to meet a range of volume and pressure requirements, HiP hydrostatic test pumps offer application versatility to meet the range on pressurized vessels available in the market. Below represents a few of the products currently employed in hydrostatic testing across the globe:

Sprague Pumps

With innovation dating back to 1947, Sprague Products developed the first air operated liquid pump specifically for hydrostatic testing roadblocks experienced within the aerospace industry. Now a timeless design, the pump’s ability to indefinitely hold liquid-air balance with minimal energy consumption is critical for both hydrostatic testing and other industrial applications.

Today, HiP offers a full line of Sprague hydraulic pumps, power units and gas boosters for various liquid output pressures up to 36,500 psi. Uncomplicated, rugged and field proven, these pumps are virtually maintenance-free, enabling operators to quickly set-up tests without fretting about the status of their pumps.

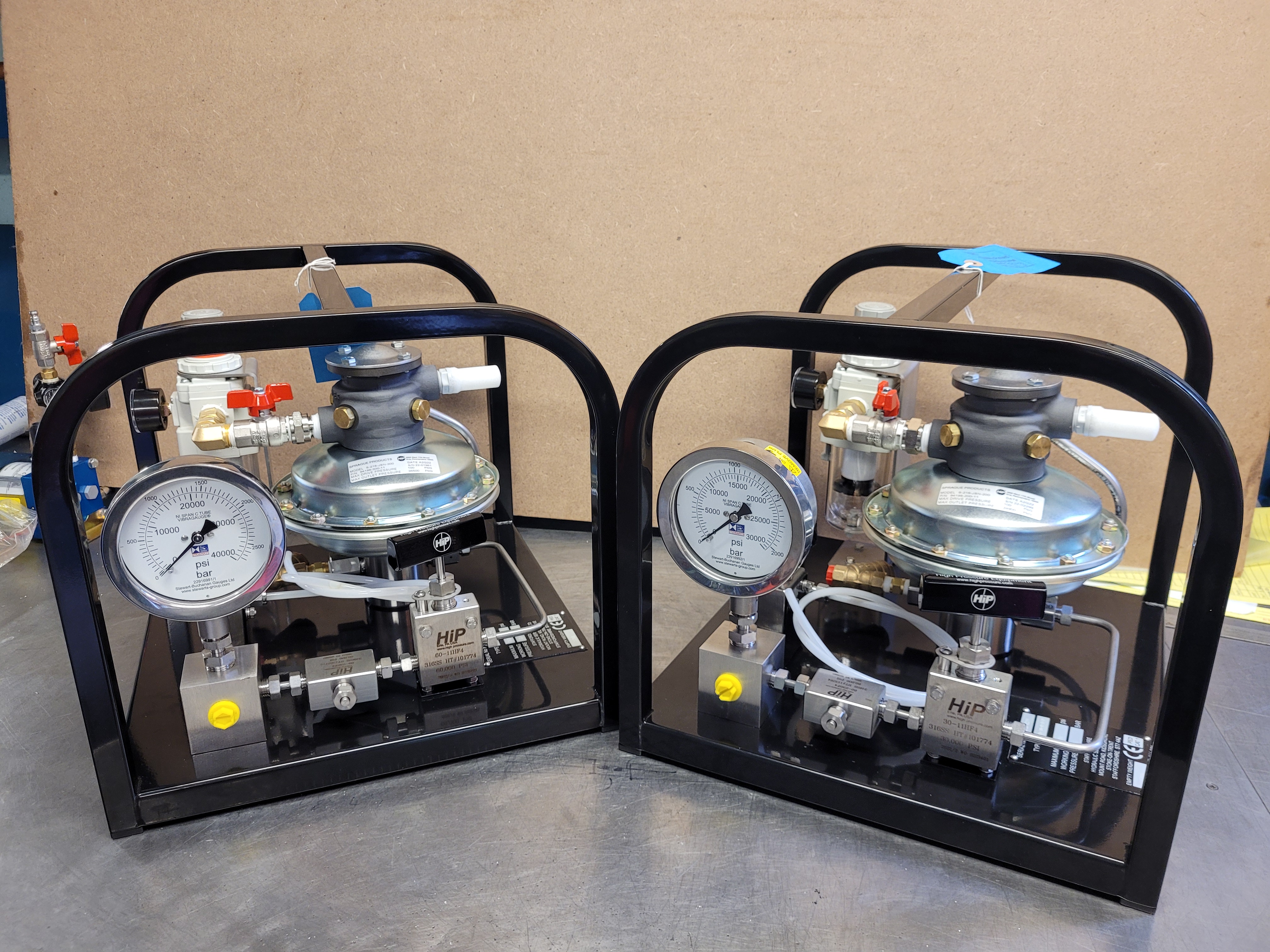

HiP T-Series Pumps

Strategically designed to solve many of the inefficiencies of traditional air-driven pump models, HiP T-Series pumps are engineered for applications up to 68,000 psi without the need for a lubricated air source. The ability for T-Series pumps to achieve a “bubble tight” pressure stall provides surety for hydrostatic testing applications, particularly when operation at maximum working pressure is a necessity.

Staffordshire Hydraulics (SHS), a subsidiary of HiP products within the United Kingdom, regularly uses T-Series pumps, as well as HiP valves, fitting and tubing, when building custom test rigs used to pressure test large diameter pipelines, hose umbilicals, and wellhead control valves. SHS additionally has an onsite pressure testing facility for customers not accustomed to regularly running pressure tests or without the facilities to safely do so.

Expert Tip!

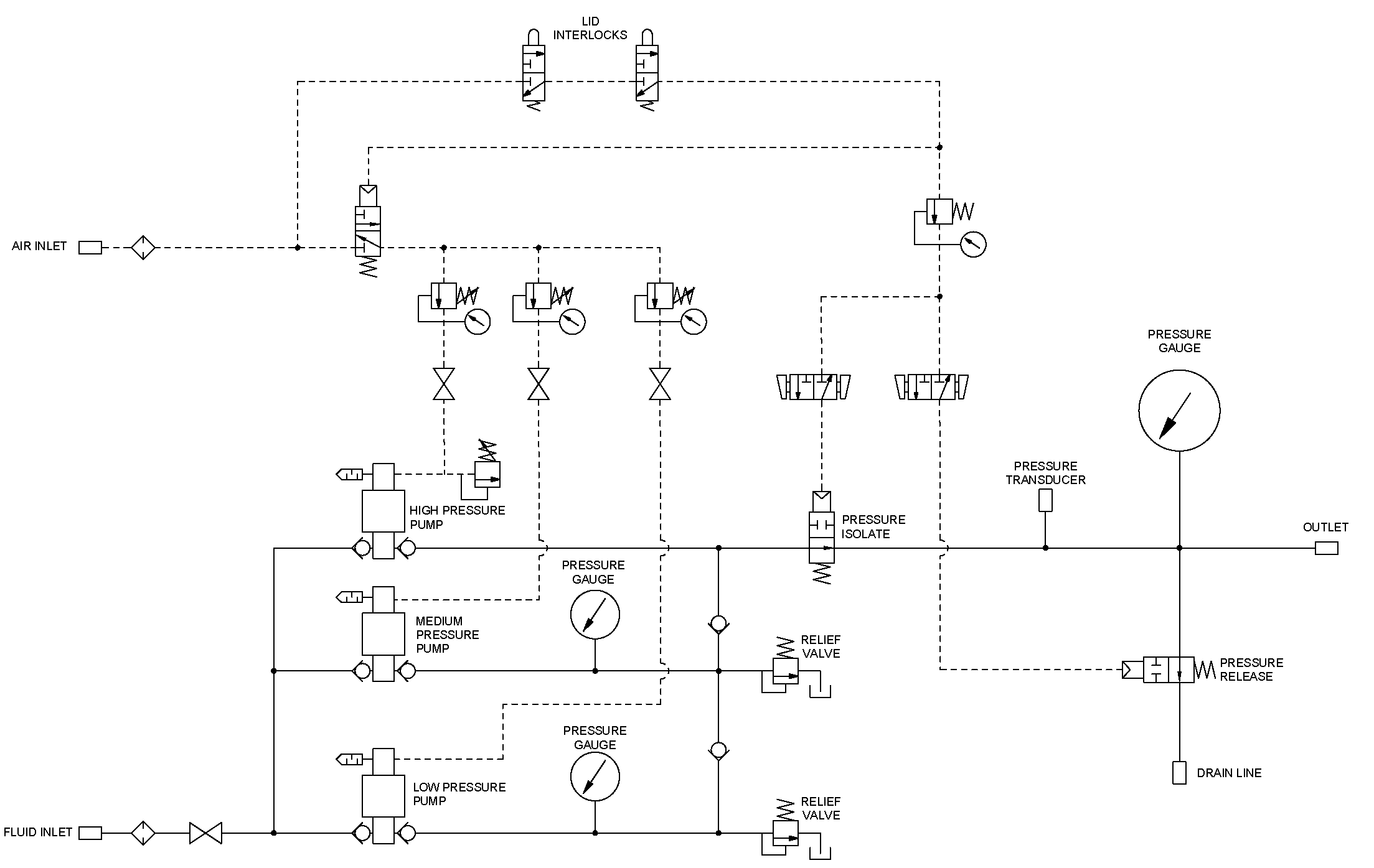

A recent project completed by SHS included creating a custom hose test unit for a manufacturer supplying product used in hydraulic systems.

Flexible hose assemblies are often overlooked in large systems, but component failure can be the most costly and damaging when hosing is at fault. For industries like aerospace, ensuring flexible hose assemblies are tested is critical before full system implementation.

SHS utilizes the HiP T-Series pump within their system design to ensure pressure requirements are met and the testing process can run its course without loss. An example of a circuit diagram for a test unit for this application is below. It is a 3 pump system for prefilling, medium pressure and high pressure applications. A full safety interlocked pressure test chamber is built into the design.

Engineered hydrostatic testing systems play a large role in certifying vessel types worldwide that are used across the global marketplace in a wide variety of applications. Their componentry, carefully selected to provide the best performance, is integral to testing success, validation and verification of safety.

About Graco High Pressure Equipment

Founded in 1954, Graco High Pressure Equipment Company (HiP) provides quality components and systems for elevated pressure applications. HiP works alongside customers to provide A+ technical/engineering support to ensure solutions are tailored to meet custom application requirements and product delivery timelines.