Airless Spray Tip Selector

Find The Right Spray Tip For Your Project

Understanding the Numbers

To make sure you always have the correct tip for the project and coating you’re using, it’s easier than you might think to “break the code” of numbers to understand tip sizing.

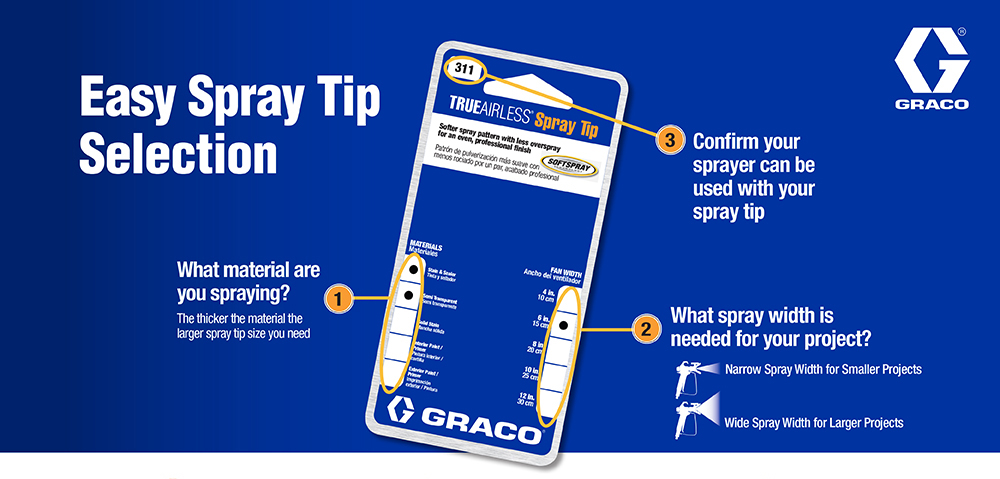

Two Basic Concepts to Remember:

- The width of the spray fan is important for the type of project you’re spraying

- The size of the spray tip opening relates to the thickness of the material you’re spraying

Breakdown of Spray Tip Numbers:

- The first digit is half of the fan width, the "5" in "517" equals a 10 inch spray fan width (5 x 2 = 10)

- The last two digits are the size of the tip opening in thousandths of an inch, the "17" in "517" means the tip hole size is .017 inch

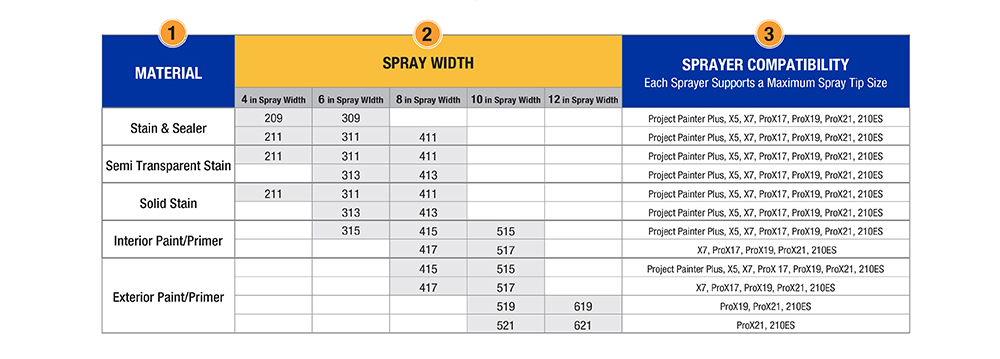

Check Your Sprayer

Before selecting a spray tip, always make sure you know what sprayer you’re using, and the size spray tips it can support. The pressure volume on each sprayer is different and this determines which size tips can be used. This information can be found in the sprayer manual. Most often the model number of the sprayer corresponds to the largest tip it can support.

Speed Advice

- Use smaller tip size when applying thinner materials such as stains and enamels

- Use larger sizes for thicker materials such as exterior, latex and oil based paints

- The larger the size of the tip hole, the faster the material leaves the gun

- A 313 tip sprays faster than a 311 or 411 tip

Understanding Tip Wear and Effects

Since most coatings have solids that cause abrasion, spray tips will wear with normal use.

When a tip wears, the orifice size increases and the fan width decreases. This causes more paint to hit a smaller area, which wastes paint and slows productivity.

It’s important to replace a tip when it gets worn to make sure you get a precise spray pattern, maximum productivity and quality finish on your project.

Tip Wear Advice

Always turn down the spray pressure as low as it can go, while still spraying a good spray pattern. This not only saves paint by reducing overspray but it also reduces tip wear and prolongs pump life.

- Tip life varies by coating. Recommended replacement times:

- Latex - Replace after 15-40 gallons

- Oils & Stains - Replace after 35-60 gallons

- Do not increase the pump pressure – this only wastes paint and causes unnecessary pump component wear.